HPL PANELS

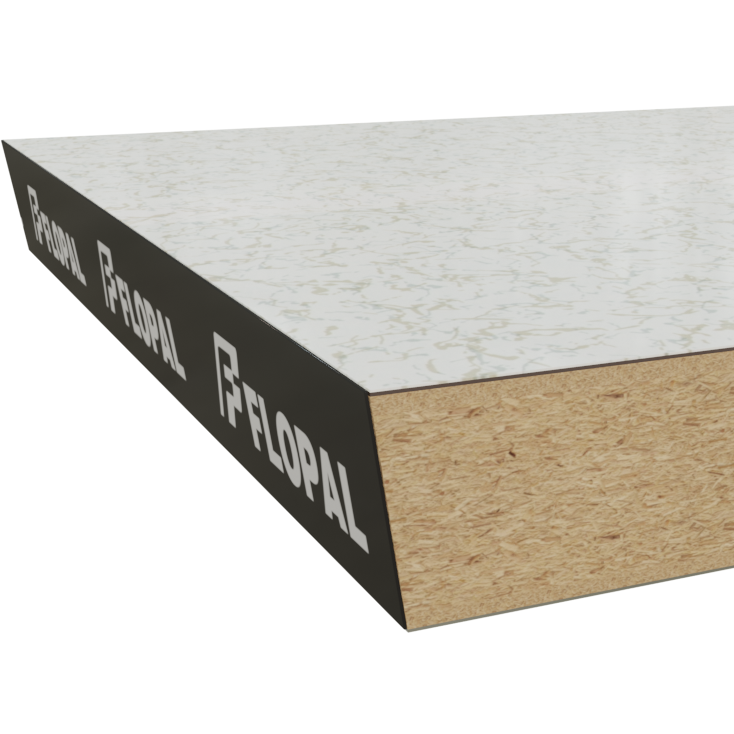

The panels are produced with an standard or antistatic 1.0 mm thick HPL (Laminate) factory bonded top surface finish. Panels can be produced with high density chipboard or monoblock calcium sulfate alternatives with A1 fire resistance as panel core.

Panels are 30/38 mm core thickness excluding top finish, bottom surface and foil, galvanized steel sheet/tray covered can be produced. To increase the load-bearing capacity and strength of the panel, the top surface coating Galvanized steel can be applied underneath.

Receiving and grounding static electricity on the floor surface In special areas that need it, the panels can have HPL conductive properties and between the panel surfaces. It is produced to provide conductivity.

| Panel Model | Panel Core | Core Thickness | Surface Finish | Top Cover | Bottom Cover | Edge | Fire Class |

|---|---|---|---|---|---|---|---|

| L-SFC30/38 | High Density Chipboard | 30/38 | 0.8 - 1.0mm HPL | - | Aluminum Foil | PVC | B1 |

| L-SMC30/38 | High Density Chipboard | 30/38 | 0.8 - 1.0mm HPL | - | Galvanised Steel | PVC | B1 |

| L-DMC30/38 | High Density Chipboard | 30/38 | 0.8 - 1.0mm HPL | Galvanised Steel | Galvanised Steel | PVC | B1 |

| L-SCT30/38 | High Density Chipboard | 30/38 | 0.8 - 1.0mm HPL | - | Galvanised Steel Tray | PVC | B1 |

| L-MCT30/38 | High Density Chipboard | 30/38 | 0.8 - 1.0mm HPL | Galvanised Steel | Galvanised Steel Tray | PVC | B1 |

| L-SFCa30/38 | Monoblock Calcium Sulphate 1500-1650 kg/m3 | 30/38 | 0.8 - 1.0mm HPL | - | Aluminum Foil | PVC | A1 |

| L-SMCa30/38 | Monoblock Calcium Sulphate 1500-1650 kg/m3 | 30/38 | 0.8 - 1.0mm HPL | - | Galvanised Steel | PVC | A1 |

| L-DMCa30/38 | Monoblock Calcium Sulphate 1500-1650 kg/m3 | 30/38 | 0.8 - 1.0mm HPL | Galvanised Steel | Galvanised Steel Tray | PVC | A1 |

| L-SCaT30/38 | Monoblock Calcium Sulphate 1500-1650 kg/m3 | 30/38 | 0.8 - 1.0mm HPL | - | Galvanised Steel Tray | PVC | A1 |

| L-MCaT30/38 | Monoblock Calcium Sulphate 1500-1650 kg/m3 | 30/38 | 0.8 - 1.0mm HPL | Galvanize Steel | Galvanised Steel Tray | PVC | A1 |